WhatsApp: +86 15163265202 | E-mail: sales@cnchandemo.com

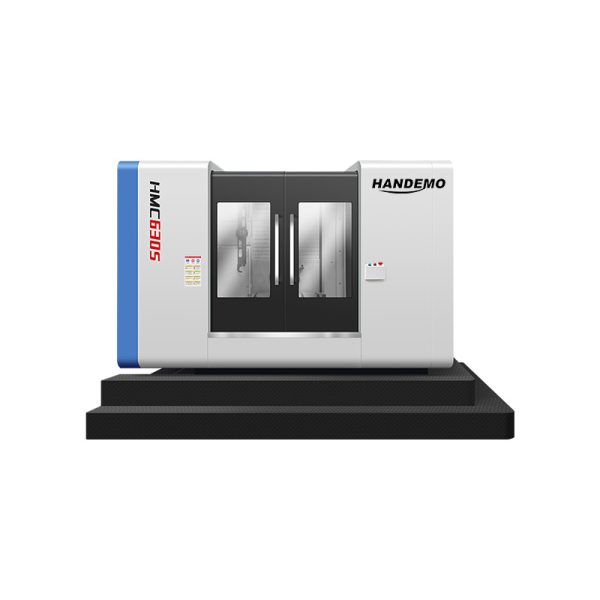

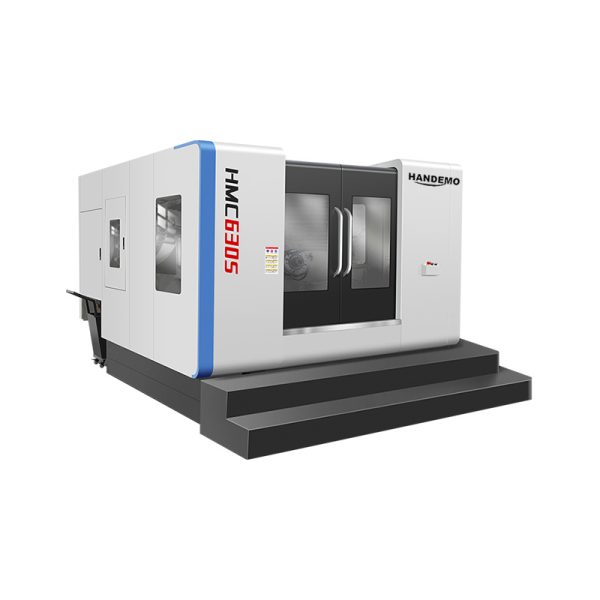

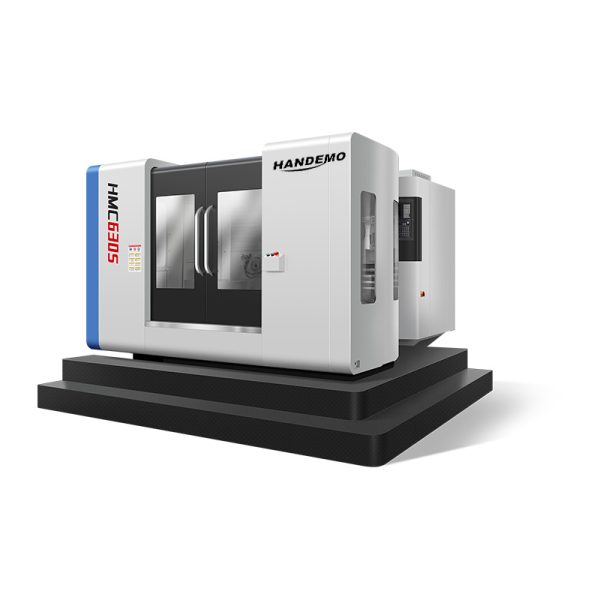

HMC630S

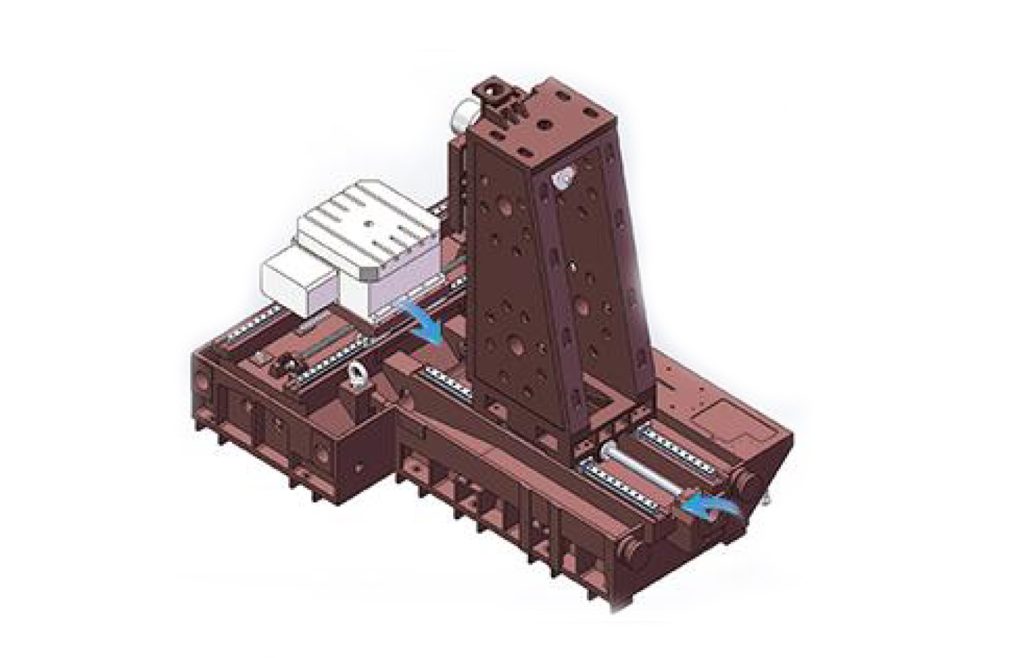

The HMC630S is a high-performance horizontal machining center designed for precision and efficiency in medium-to-large part production.The HMC630S offers flexible configuration options including gear-driven spindles, pallet changers, and compatibility with major CNC systems (Siemens/FANUC), making it an ideal solution for automotive, aerospace, and general machinery manufacturers seeking reliable batch production capability.