WhatsApp: +86 15163265202 | E-mail: sales@cnchandemo.com

HMC1075

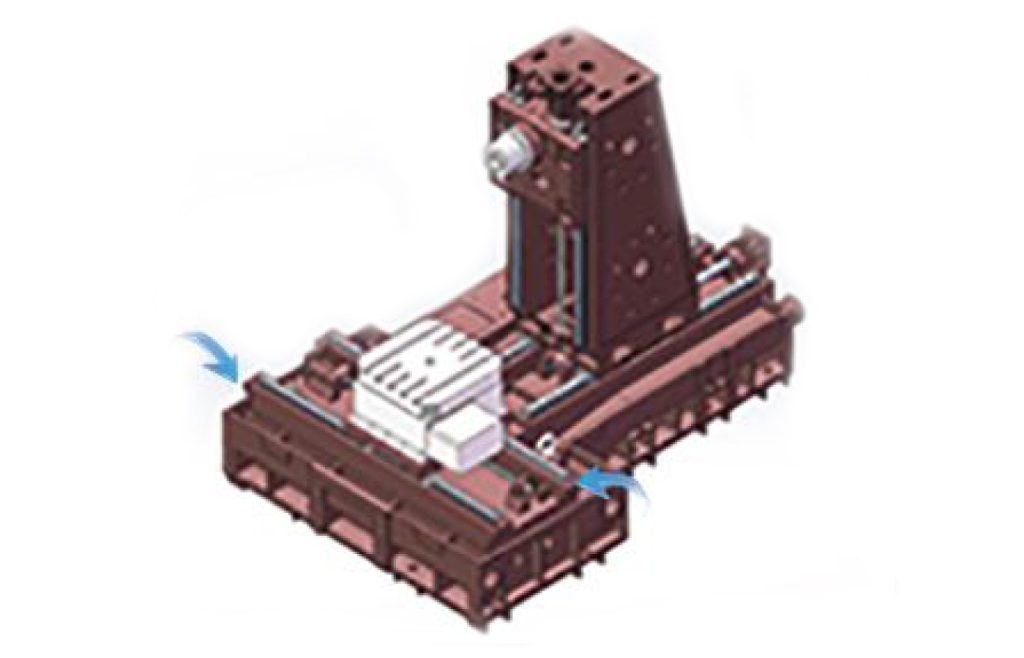

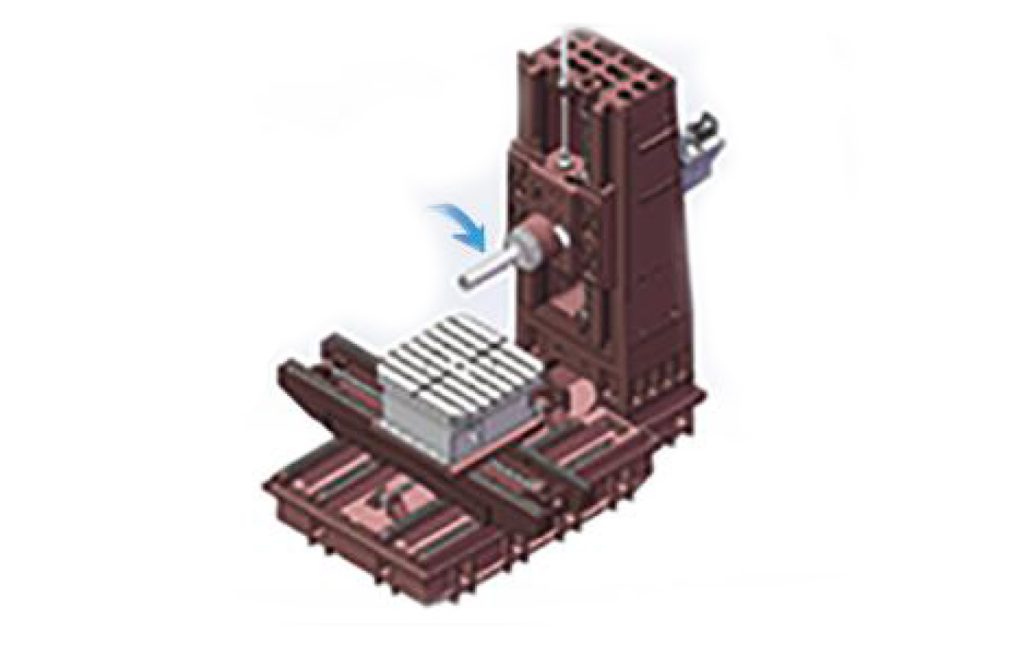

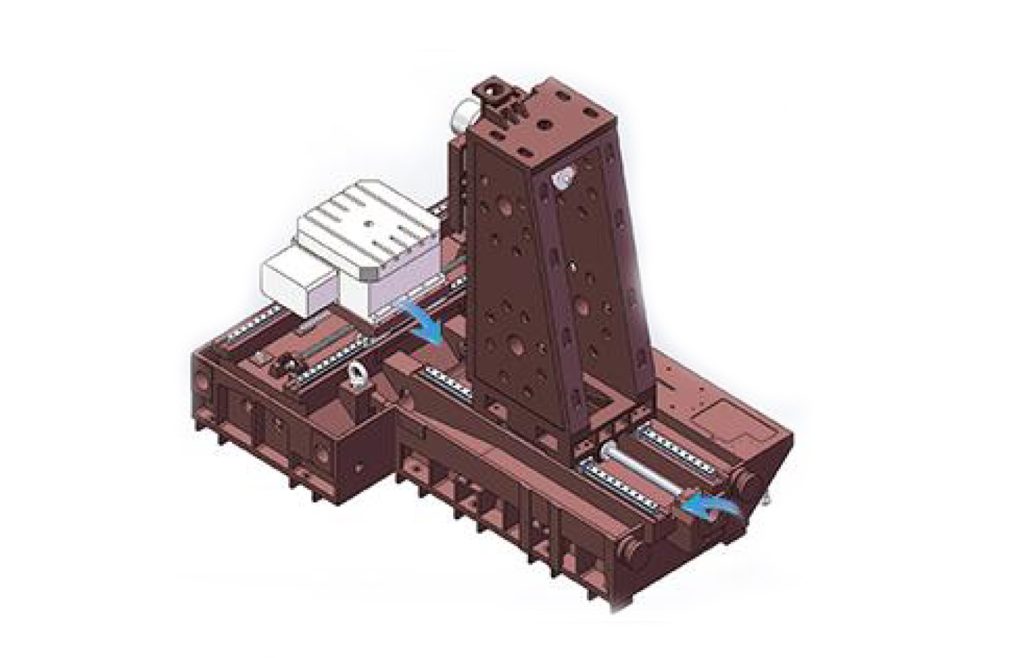

HMC1075 is a high-performance horizontal machining center designed for precision and efficient large and medium-sized parts processing. Equipped with a high-rigidity bed and precision spindle, it supports four-axis/five-axis linkage and is suitable for complex surface processing in the fields of aerospace, automotive molds, energy equipment, etc.