WhatsApp: +86 15163265202 | E-mail: sales@cnchandemo.com

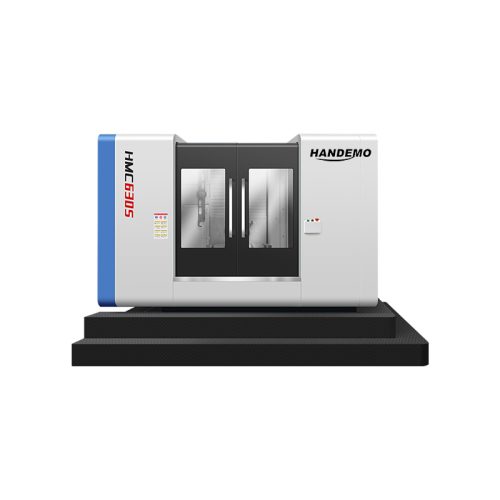

HMC1000S

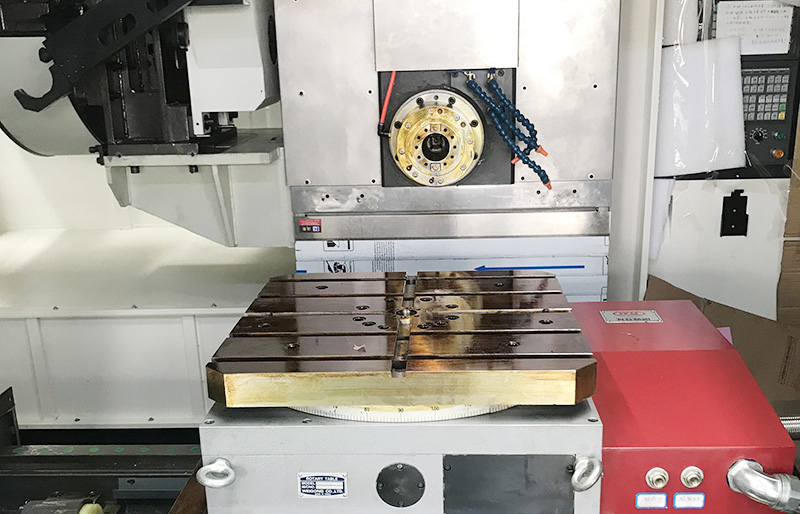

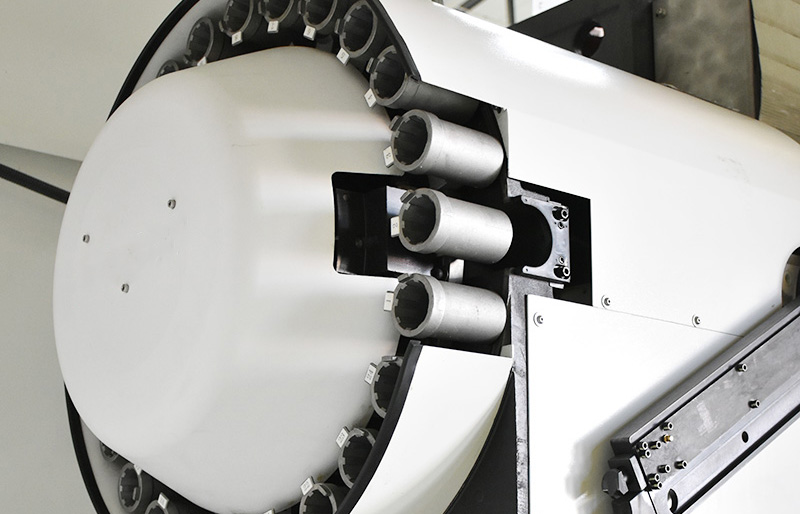

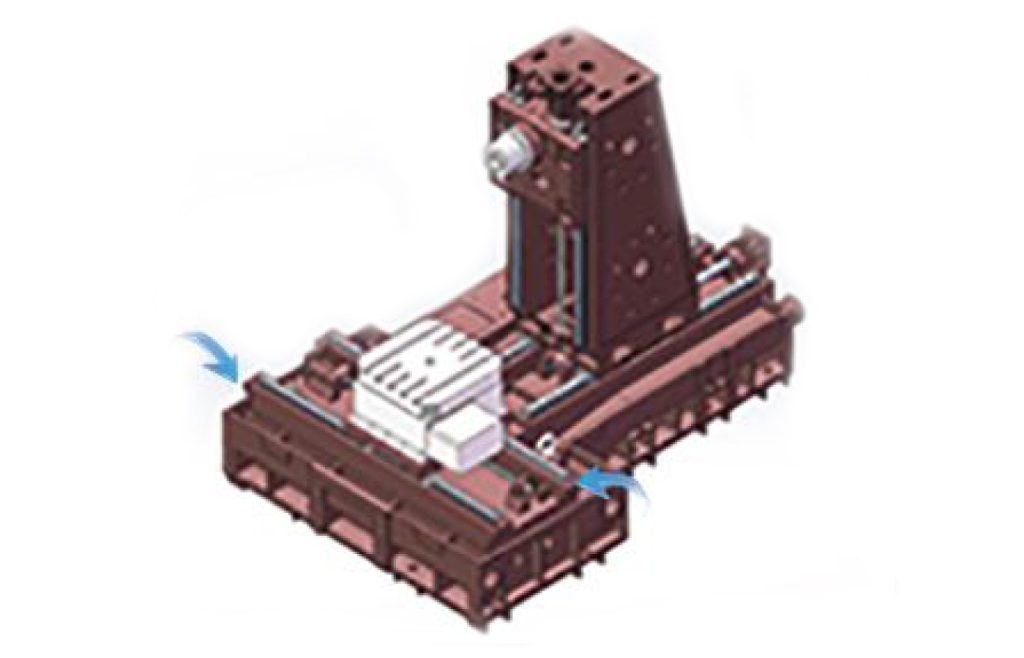

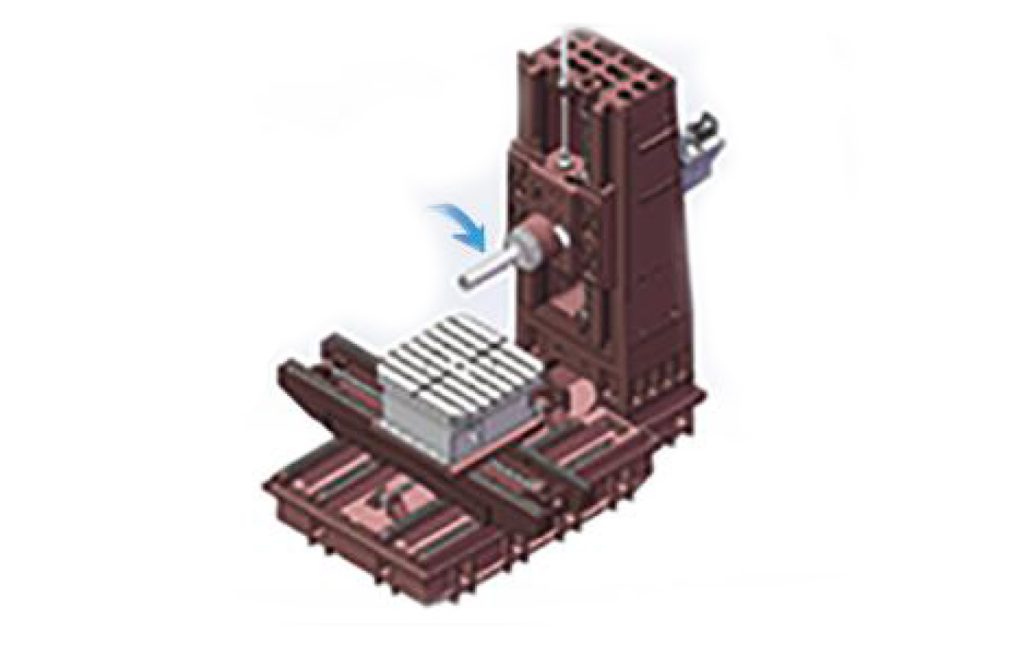

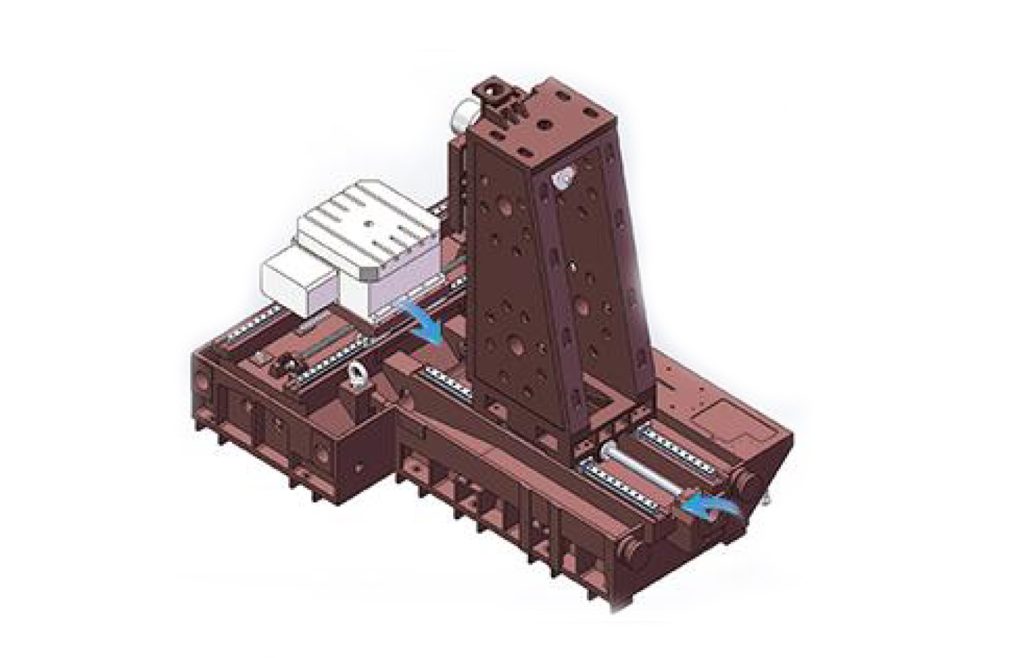

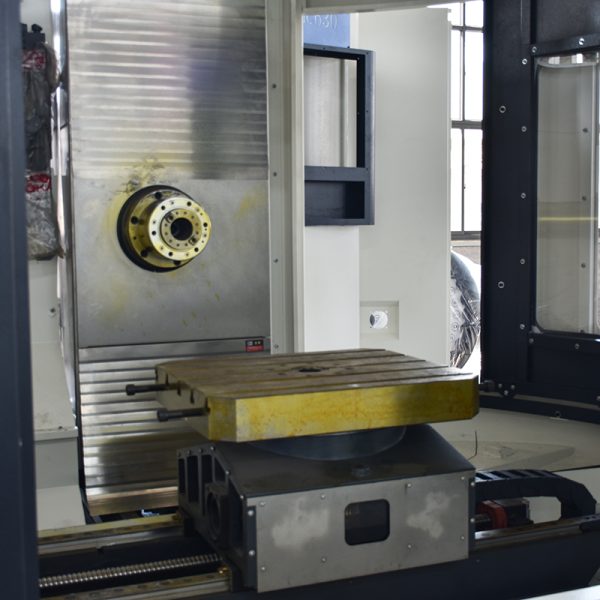

HMC1000S is a high-end horizontal machining center for heavy-duty precision machining. It adopts a reinforced bed structure and a 1000×1000mm large load-bearing worktable (maximum load 4000kg), which is optimized for the machining of complex parts such as large aerospace structures and heavy shells of energy equipment. The double worktable exchange system can be optionally equipped to meet the stringent requirements of high-end manufacturing for precision, efficiency and automation.