WhatsApp: +86 15163265202 | E-mail: sales@cnchandemo.com

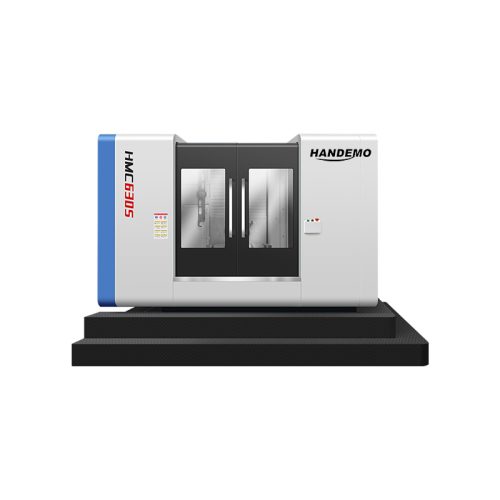

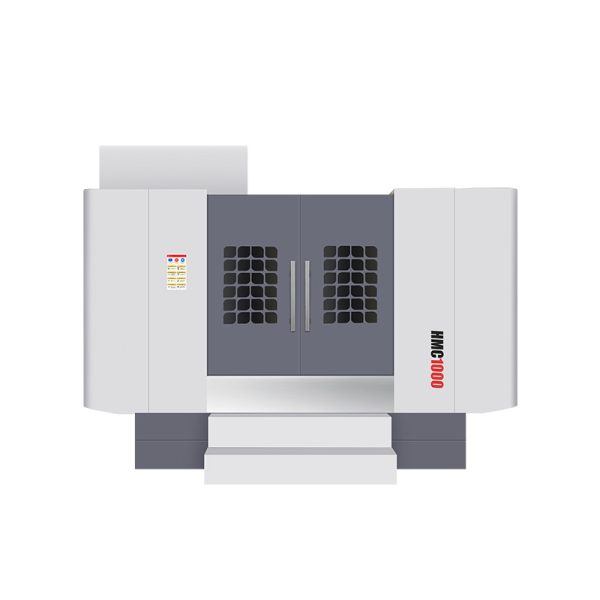

HMC1000

The HMC1395 horizontal machining center is a large-scale precision machining equipment developed for the high-end manufacturing field. It supports five-axis linkage machining and online measurement functions, which significantly improves the machining efficiency and quality stability of complex surfaces. The optional double exchange table configuration further optimizes the production cycle, allowing the equipment to ensure machining accuracy while taking into account the efficiency requirements of mass production.

WhatsApp: +86 15163265202

E-mail: sales@cnchandemo.com