WhatsApp: +86 15163265202 | E-mail: sales@cnchandemo.com

Introduction

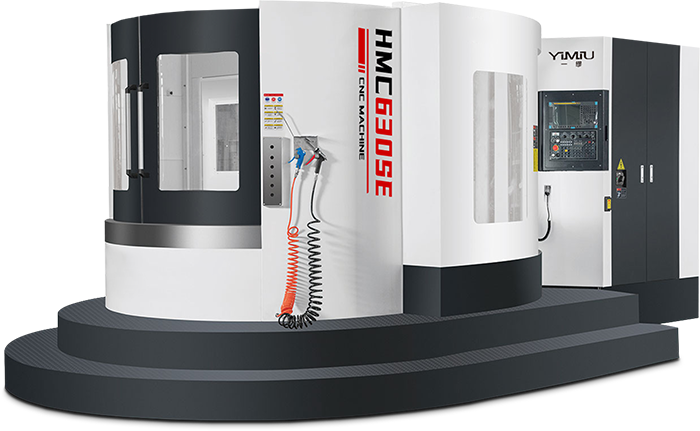

The horizontal machining center is a high-efficiency CNC machine tool with a horizontal spindle axis. The workpiece is processed on multiple surfaces through a workbench or fixture. It is particularly suitable for mass production of box-type and large and complex parts. Its core feature is that it is equipped with an automatic tool change system and a rotary table, which can complete milling, drilling, tapping and other multi-process processing in one clamping.

| HORIZONTAL MILLING MACHINE | HMC630S | HMC1000S | HMC1400S | HMC630 (Inverted T) |

HMC800 (Inverted T) |

|---|---|---|---|---|---|

| Distance from spindle end to worktable(mm) | 630*630 | 1000*1000 | 1400*1400 | 630*630 | 800*800 |

| Spindle type | BT50-190 | BT50-45° | BT50-45° | BT50-190 | BT50-200 |

| X-axis travel(mm) | 1000 | 1800 | 1800 | 1000 | 1300 |

| Y-axis travel(mm) | 800 | 1000 | 1300 | 800 | 1150 |

| Z-axis travel(mm) | 850 | 1300 | 1500 | 850 | 1000 |

| Spindle speed (rpm/min) | 6000 | 3000 | 2000 | 6000 | 6000 |

| Spindle motor power | 15KW | 22KW | 22KW | 15KW | 22KW |

| Tool magazine capacity | 24 | 24 | 24 | 24 | 24 |

| Horizontal turntable | 630 turntable | 1000 turntable | 1400 turntable | 630 turntable | 800 turntable |

| HORIZONTAL MILLING MACHINE | HMC1000 (positive T) |

HMC1075 | HMC1395 | HMC800 |

|---|---|---|---|---|

| Distance from spindle end to worktable(mm) | 1000*1000 | 1300*600 | 1400*700 | 800*800 |

| Spindle type | BT50-190 | BT40-150 | BT50-190 | BT50-200 |

| X-axis travel(mm) | 1300 | 1000 | 1300 | 1300 |

| Y-axis travel(mm) | 1100 | 750 | 800 | 1150 |

| Z-axis travel(mm) | 1200 | 800 | 750 | 1000 |

| Spindle speed (rpm/min) | 6000 | 6000 | 6000 | 6000 |

| Spindle motor power | 22KW | 11KW | 15KW | 22KW |

| Tool magazine capacity | 24 | 24 | 24 | 24 |

| Horizontal turntable | 1000 turntable | 630 turntable | 630 turntable | 800 turntable |

Our exclusive services

“We look forward to hearing from you and helping you find the perfect machining solution for your business.”

Warranty

We offer a comprehensive 5 - year warranty on all our CNC slant bed lathes, ensuring your peace of mind.

Spare parts network

Relying on a complete spare parts storage network, we provide original spare parts in the shortest time.

Onsite training

We provide on-site guidance and training to ensure your team can quickly master equipment operation skills.

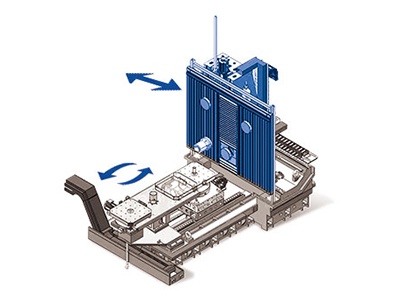

Positive T-type double exchange structure

- The worktable moves forward and backward along the Z axis, and the column moves left and right along the X axis.

- The moving parts of the structure are lighter and more suitable for precision machining.

- Suitable industry: Batch finishing of box-type workpieces.

Inverted T-type double exchange structure

- The worktable moves left and right along the X-axis, and the column moves forward and backward along the Z-axis.

- Compact structure, small footprint, suitable for occasions with limited space.

- Suitable industries: Suitable for processing flat, porous or multi-faceted batch parts.

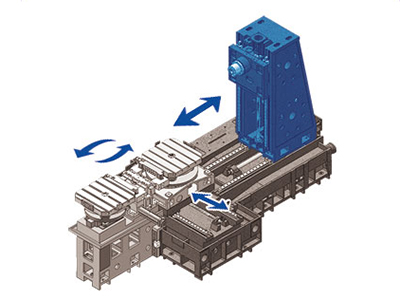

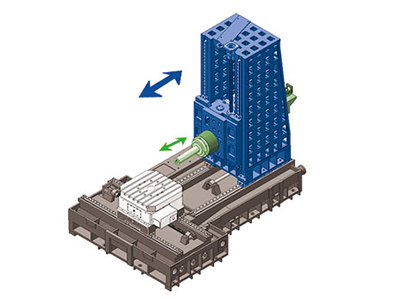

Positive T-type structure

- The worktable moves forward and backward along the Z axis, and the column moves left and right along the X axis.

- The moving part of this structure is lighter and more suitable for precision machining.

- Suitable industries: widely used in aerospace, automobile, mold, shipbuilding and general machinery industries.

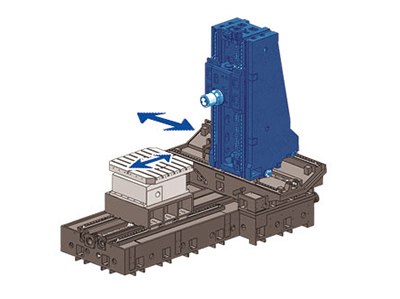

Inverted T-type telescopic spindle structure

- One-time processing of deep holes can eliminate the deviation error of long tools.

- For difficult-to-cut materials such as steel parts, stainless steel parts, forging parts, etc., the cutting performance is better and the rigidity is stronger.

- Suitable industries: The needle can be widely used in small and medium-sized boxes, engine gearboxes, new energy, wind power component processing, mold processing, and other mechanical manufacturing fields.

Trusted by Industries for Precision Turning

Choice for all industries

Our CNC Milling Machine deliver top performance and reliability across a wide range of industries.

Automotive: Engine parts, transmission components

Mechanical Engineering: High-precision machine parts

Medical Technology: Surgical instruments, implants

Aerospace: Critical aircraft components

Ready to Upgrade Your Production Line?

Consult now and enjoy free machine training!