WhatsApp: +86 15163265202 | E-mail: sales@cnchandemo.com

CNC Mill-Turn Machines

Multifunctional composite processing, turning, milling, drilling, tapping and threading in one.

TCK56Y

——5 series straight Y structure

- Cutting length: 400mm

- Cutting diameter: 300mm

- Y-axis travel: ±30mm

TCK56Y-1000

——5 series straight Y structure

- Cutting length: 930mm

- Cutting diameter: 300mm

- Y-axis travel: ±30mm

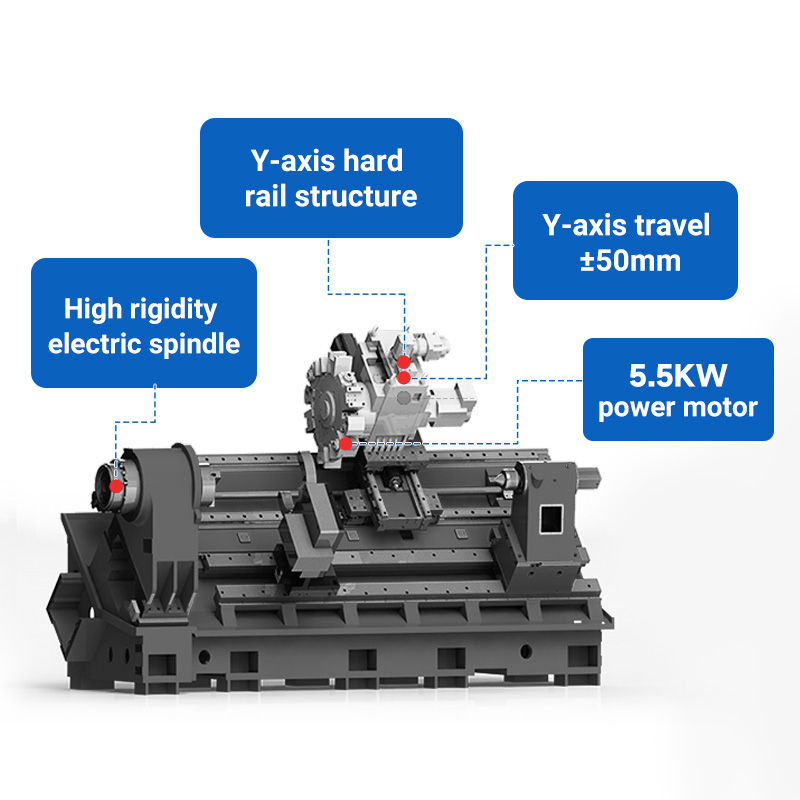

TCK600Y

——6 series straight Y structure

- Cutting length: 500mm

- Cutting diameter: 430mm

- Y-axis travel: ±50mm

TCK600Y-1000

——6 series straight Y structure

- Cutting length: 1000mm

- Cutting diameter: 430mm

- Y-axis travel: ±50mm

TCK63Y-1500

——6 series straight Y structure

- Cutting length: 1500mm

- Cutting diameter: 480mm

- Y-axis travel: ±75mm

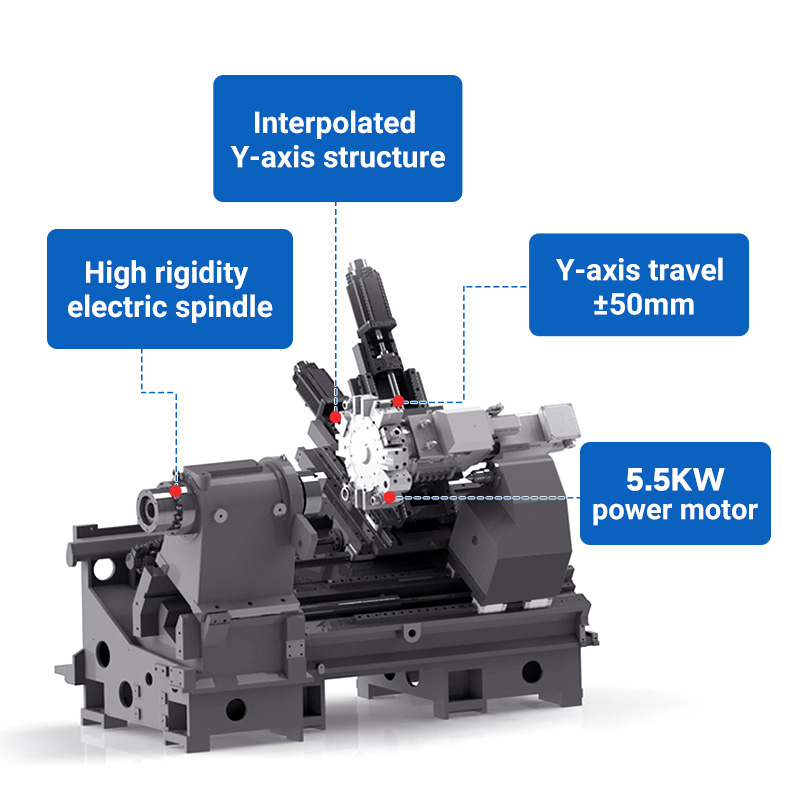

TCK2100LY

——C-series interpolation Y structure

- Cutting length: 500mm

- Cutting diameter: 350mm

- Y-axis travel: ±50mm

TCK600SY

——S series double spindle structure

- Cutting length: 500mm

- Cutting diameter: 350mm

- Y-axis travel: ±50mm

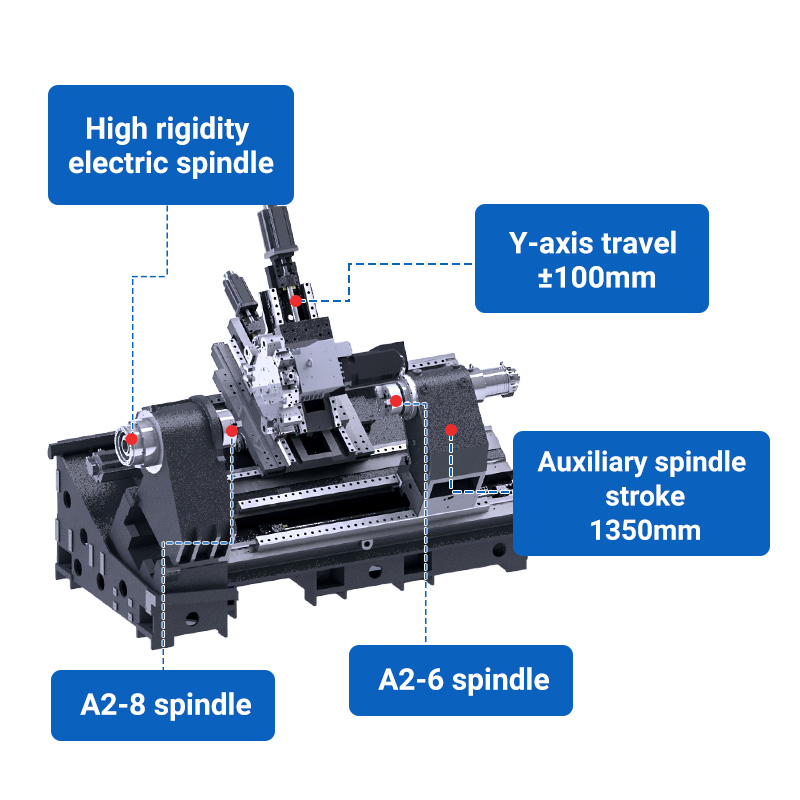

TCK3100SY

——S series double spindle structure

- Cutting length: 1000mm

- Cutting diameter: 500mm

- Y-axis travel: ±100mm

Multifunctional processing

Integrated turning, milling, drilling, boring, tapping and other functions.

Power Motor

5.5KW high power milling motor.

Heavy-duty structural bed

Support: 5-series straight Y structure, 6-series straight Y structure, C-series interpolation Y structure and S-series dual spindle structure.

Our exclusive services

5-year warranty

Free repair and maintenance to factory condition within five years.

AI-Powered Smart Lathe

AI Model-Powered Smart Features: Programming, Human-Machine Dialogue, Machine Tool Diagnostics & Q&A.

Industrial IoT System

Digital Cloud Platform for Real-Time Equipment Monitoring, Fault Diagnostics & Remote Control.

Custom Cutting Tool Solutions

Customized research and development of special tools, digital and intelligent tool management.