WhatsApp: +86 15163265202 | E-mail: sales@cnchandemo.com

Hey there! Have you ever wondered about the magic behind creating precisely – shaped metal parts? Lathes play a huge role in this. But did you know there are different types? Specifically, the CNC lathe and the regular lathe? Let’s dive in and explore what sets them apart.

The Basics of Lathes

What is a Lathe?

Before we compare, let’s understand what a lathe is. A lathe is a machine that rotates a workpiece against a cutting tool. It’s like a spinning canvas where the cutting tool carves out shapes. Whether it’s a simple cylindrical rod or a complex component, lathes have been shaping materials for ages.

Importance in Manufacturing

Lathes are essential in the manufacturing world. They help create parts for everything from cars to household appliances. Without them, many of the products we use daily wouldn’t exist. So, both the CNC lathe and the regular lathe have a big job to do. But how do they differ?

Control Mechanisms: The Heart of the Difference

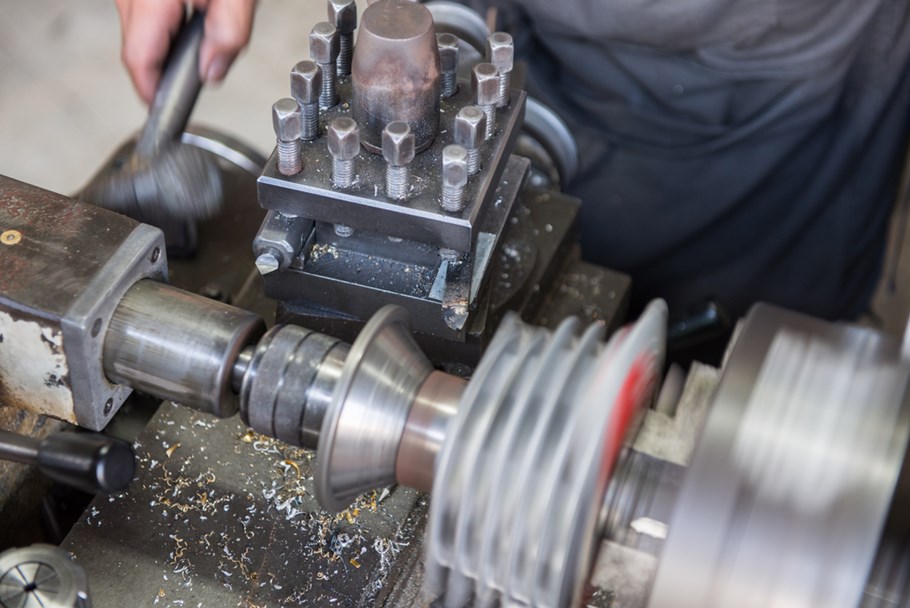

Regular Lathe Control

Manual Operation

A regular lathe, also known as a manual lathe, is operated by hand. The machinist controls the movement of the cutting tool using levers and handles. It’s like driving a car with a manual transmission. You have to adjust every movement precisely, based on your experience and skill.

Operator Dependence

The quality of the work on a regular lathe depends a lot on the operator. If the operator isn’t skilled enough, the final product might not be accurate. It’s like a painter’s work – the outcome relies on the artist’s hand.

CNC Lathe Control

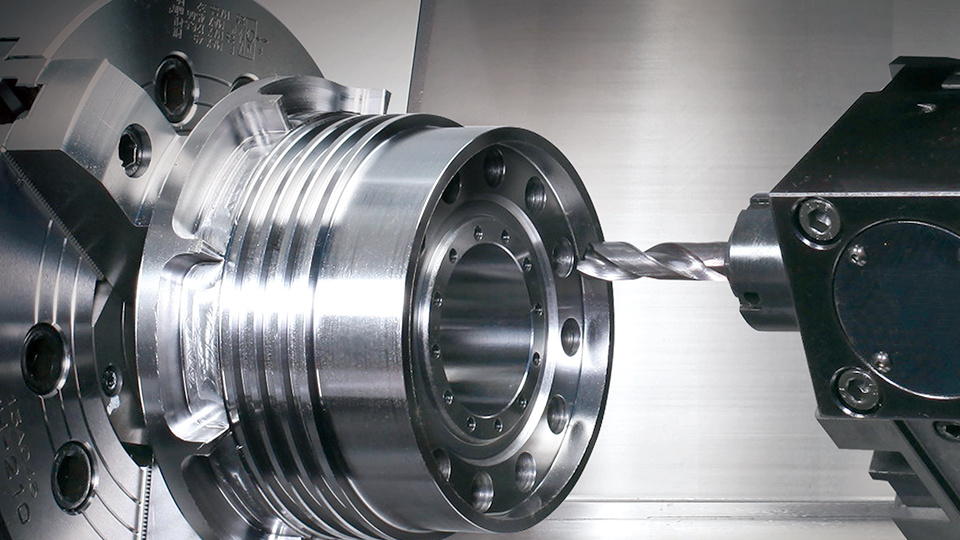

Computer – Numerical Control

A CNC lathe uses Computer Numerical Control. A pre – written program tells the machine exactly what to do. It’s like having a GPS for the cutting tool, guiding it to the right place with pinpoint accuracy.

Program – Driven Precision

Once the program is loaded, the CNC lathe works autonomously. It follows the instructions without any human error (assuming the program is correct). This makes the process highly repeatable and accurate.

Precision and Accuracy

Regular Lathe Precision

Human – Error Factor

Since a regular lathe is manually operated, there’s room for human error. Even the most skilled machinist can make mistakes. Maybe a slight slip of the hand or a miscalculation can affect the final product. It’s like trying to draw a perfectly straight line by hand – it’s tough to get it right every time.

Limited Tolerances

Regular lathes usually have larger tolerances. This means the parts they produce might not be as precisely sized as those from a CNC lathe. For applications that need extreme accuracy, a regular lathe might fall short.

CNC Lathe Precision

Consistent Accuracy

A CNC lathe can achieve incredibly high precision. It can produce parts with tolerances as small as a few thousandths of an inch. Every cut is exactly the same as long as the program remains unchanged. It’s like using a laser – guided system to make cuts.

Repeatability

If you need to produce multiple identical parts, a CNC lathe is a champ. It can make the same part over and over again with the same level of accuracy. This is crucial in mass production.

Production Speed and Efficiency

Regular Lathe Speed

Slower Operation

Operating a regular lathe is a slower process. The machinist has to adjust each movement, which takes time. It’s like walking compared to running. For large – scale production, this can be a bottleneck.

Interruptions and Breaks

Since it’s a manual process, the operator needs breaks. Also, any adjustments or corrections during the process add to the overall time taken.

CNC Lathe Speed

Faster Production

A CNC lathe can work at a much faster pace. Once the program is set, it can run continuously without breaks (except for maintenance). It’s like having a machine that never gets tired.

Optimized Processes

CNC lathes can optimize the cutting process. They can adjust the speed and feed rate based on the material and the shape being cut. This increases efficiency and reduces production time.

Flexibility in Design

Regular Lathe Design Limitations

Complexity Challenges

Creating complex shapes on a regular lathe is difficult. It requires a lot of skill and time. The machinist has to make multiple adjustments to achieve the desired shape. It’s like trying to build a complex puzzle with your hands alone.

Limited Customization

Customizing parts on a regular lathe can be a hassle. Each change might require a new setup, which takes time and effort.

CNC Lathe Design Flexibility

Easy Complex Shape Creation

With a CNC lathe, creating complex shapes is a breeze. The computer program can be easily modified to create any design you can think of. It’s like having a 3D printer for metal parts, but with even more control.

Quick Customization

At Shandong Handemo Technology Co., Ltd., we offer customized CNC lathe services. Changing the design of a part is as simple as updating the program. This allows for quick and easy customization, whether it’s a one – off prototype or a large – batch order.

Conclusion

In conclusion, both the CNC lathe and the regular lathe have their own strengths and weaknesses. Regular lathes are great for small – scale, simple jobs and for those who appreciate the art of manual machining. On the other hand, CNC lathes offer unparalleled precision, speed, and flexibility, making them ideal for mass production and complex designs. At Shandong Handemo Technology Co., Ltd., we understand the unique capabilities of CNC lathes and offer top – notch products and customized services to meet your manufacturing needs.

FAQs

- Can a regular lathe be upgraded to a CNC lathe?

Yes, in some cases, regular lathes can be retrofitted with CNC systems. But it depends on the lathe’s design and condition. - Which is more suitable for small – batch production?

For small – batch production, a regular lathe might be more cost – effective if the parts are simple. But if precision is key, a CNC lathe could be a better choice. - How long does it take to learn to operate a CNC lathe?

Learning to operate a CNC lathe can take a few weeks to a few months, depending on your prior experience and the complexity of the machine. - Do CNC lathes use more electricity than regular lathes?

CNC lathes generally use more electricity due to their computer systems and advanced components. But the efficiency gains often outweigh the additional cost. - Can a regular lathe produce parts as accurately as a CNC lathe?

While a highly skilled operator can produce accurate parts on a regular lathe, a CNC lathe can consistently produce parts with higher precision and less variation.