WhatsApp: +86 15163265202 | E-mail: sales@cnchandemo.com

TCK63Y-3000

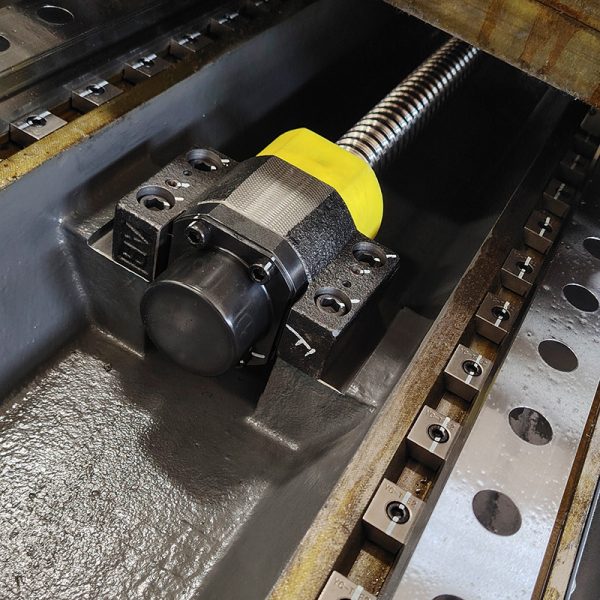

The TCK63Y – 3000 is a revolutionary CNC mill – turn machine, meticulously engineered to meet the most demanding requirements of modern large – scale manufacturing. By seamlessly integrating milling and turning operations into a single, high – performance platform, it offers a comprehensive and efficient machining solution.

- Integrated Milling and Turning for Unrivaled Productivity

- Advanced Motion Control for Tightest Tolerances

- Intuitive CNC Interface for Effortless Operation