WhatsApp: +86 15163265202 | E-mail: sales@cnchandemo.com

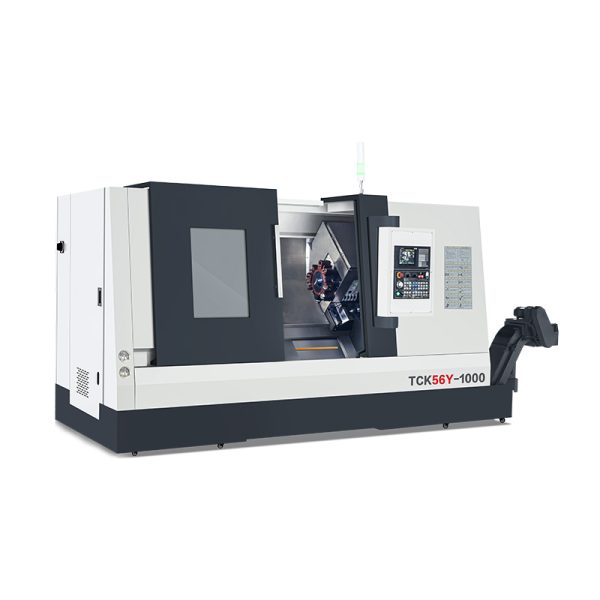

TCK56Y-1000

The TCK56Y – 1000 is a cutting – edge CNC mill – turn machine, meticulously engineered to meet the diverse and exacting demands of modern manufacturing. By seamlessly integrating milling and turning operations, it offers a comprehensive machining solution in a single platform. With its advanced technologies, robust construction, and enhanced capabilities, the TCK56Y – 1000 is the go – to choice for industries ranging from aerospace and automotive to energy and medical device manufacturing.

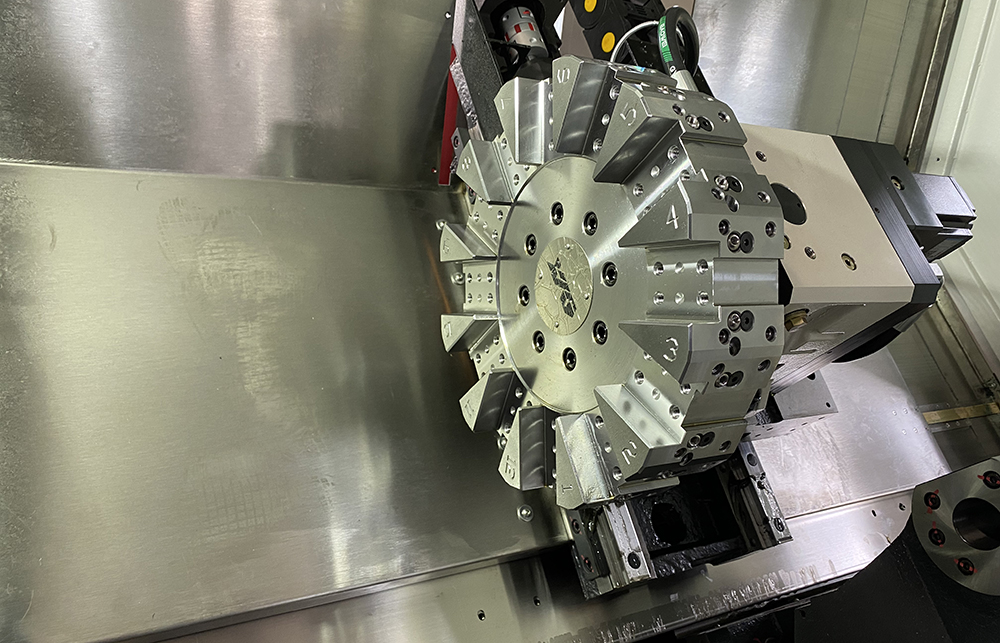

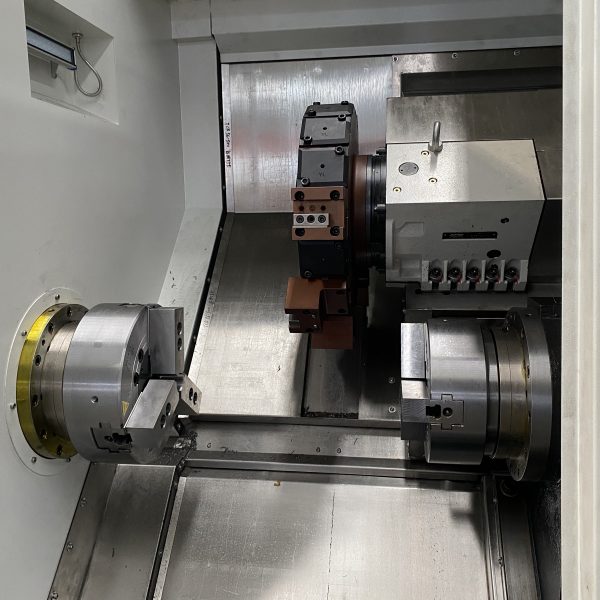

- Integrated Milling and Turning for One – Stop Precision

- High – Torque, High – Speed Spindle for Superior Machining Power

- Intuitive CNC Interface for Effortless Operation