WhatsApp: +86 15163265202 | E-mail: sales@cnchandemo.com

CNC vertical milling machine

Supports milling, drilling and tapping, increasing production efficiency by 65%.

VMC1890

- Max. Spindle Speed: 12000 r/min

- X-Axis Travel Distance: 1800mm

- Y-Axis Travel Distance: 900mm

VMC1690

- Max. Spindle Speed: 12000 r/min

- X-Axis Travel Distance: 1600mm

- Y-Axis Travel Distance: 900mm

VMC1580

- Max. Spindle Speed: 12000 r/min

- X-Axis Travel Distance: 1500mm

- Y-Axis Travel Distance: 800mm

VMC1370

- Max. Spindle Speed: 12000 r/min

- X-Axis Travel Distance: 1300mm

- Y-Axis Travel Distance: 700mm

VMC1165

- Max. Spindle Speed: 8000 r/min

- X-Axis Travel Distance: 1100mm

- Y-Axis Travel Distance: 650mm

VMC1160

- Max. Spindle Speed: 8000 r/min

- X-Axis Travel Distance: 1100mm

- Y-Axis Travel Distance: 600mm

VMC855

- Max. Spindle Speed: 8000 r/min

- X-Axis Travel Distance: 800mm

- Y-Axis Travel Distance: 550mm

VMC850

- Max. Spindle Speed: 8000 r/min

- X-Axis Travel Distance: 800mm

- Y-Axis Travel Distance: 500mm

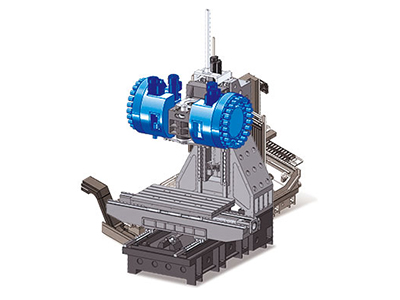

Double tool magazine structure

Compared with traditional tools, more tools are used, and processing efficiency is improved by 56%-60%.

Suitable industries: mold bases, mold frames, molds, and various parts processing that use many tools.

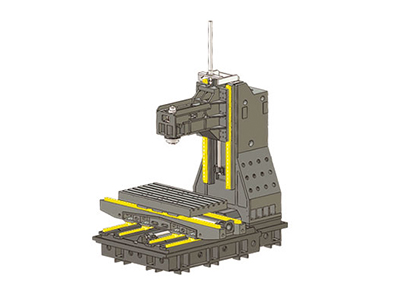

Three-hard rail structure

Can withstand large cutting forces and vibrations ensuring machining stability and precision.

Suitable industries: Widely used in industries with high machining precision and stability requirements.

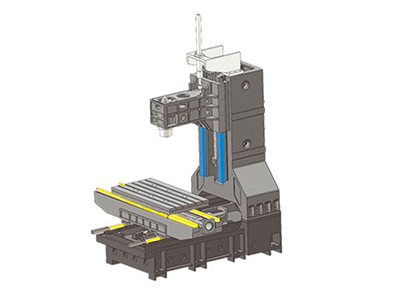

Two-wire and one-hard structure

Combines the advantages of linear rails and hard rails, with high speed and strong load-bearing capacity.

Suitable industries: Suitable for processing scenarios with high requirements for processing accuracy and need to withstand large loads.

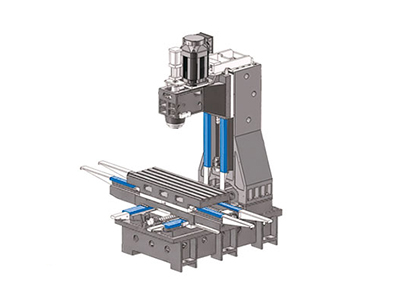

Three-line rail structure

Fast speed, high precision.Small friction coefficient, fast response.

Suitable industry: Suitable for customers with high processing precision requirements.

Our exclusive services

5-year warranty

Free repair and maintenance to factory condition within five years.

AI-Powered Smart Lathe

AI Model-Powered Smart Features: Programming, Human-Machine Dialogue, Machine Tool Diagnostics & Q&A.

Industrial IoT System

Digital Cloud Platform for Real-Time Equipment Monitoring, Fault Diagnostics & Remote Control.

Custom Cutting Tool Solutions

Customized research and development of special tools, digital and intelligent tool management.